Home> Recycling materials complete solutions>

This video introduces recycling materials technology solutions. Polynk can provide a whole solution. Any interests, please send email to alex@polynk.com

-

PET bottle bales

-

PET flakes

-

PET pellets

PET Pellets Application

Bottle-to-package

Post-consumer PET bottles are produced through specific processes; recycling,washing, sorting,

pelletizing extruding, thermoforming to produce packaging products such as fruit and vegetable

boxes, daily necessities boxes, electronic product packaging boxes, etc.

Bottle-to-filament

Post-consumer PET bottles are recycled into micro denier filament through crushing, washing,

pelletizing, and spinning processes.

The products made by micro-denier filament are more flexible, skin-friendly, and eco-friendly.

Bottle-to-bottle

Post-consumer PET bottles are recycled into rPET flakes,

The regenerative food-grade PET flakes conform to the quality index requirements of downstream

food

packaging and are used for bottle blowing and packing which can directly contact food after

pelletizing and SSP processes in the late stage(FDA Approval).

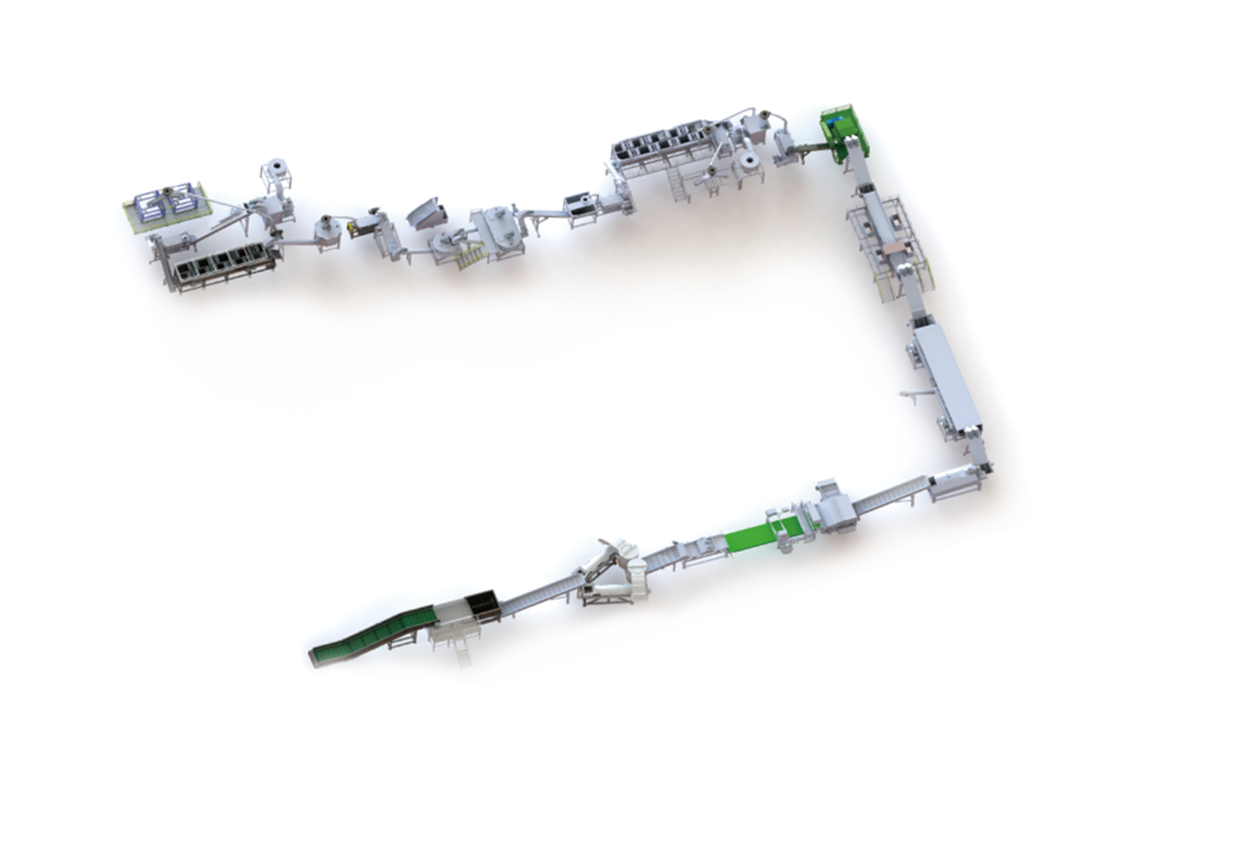

PET Bottle Recycling Process

The "Green and Recyclable Journey", visiting of exhibitors to Chinaplas 2021,. second stop, we came to Jinwu renewable resourse park, leading manufacturer of PET recycled material, PSF(PET Staple Fiber) etc, for more details, send email to alex@polynk.com

Main technical parameters

For the total power, 70% is actual power while 30% is power margin.

Main Functional Machine Introduction

-

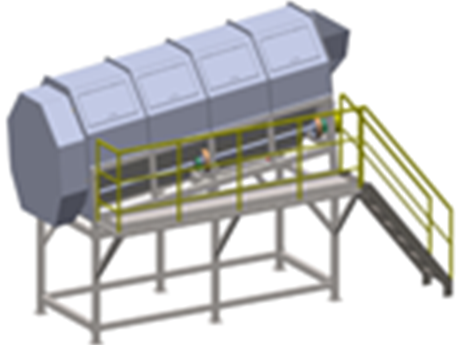

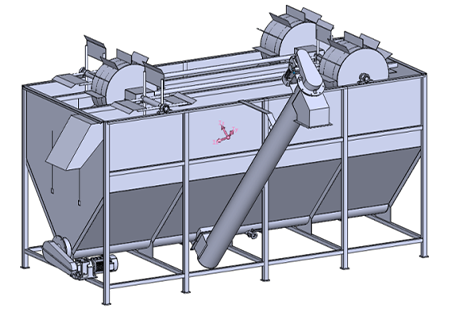

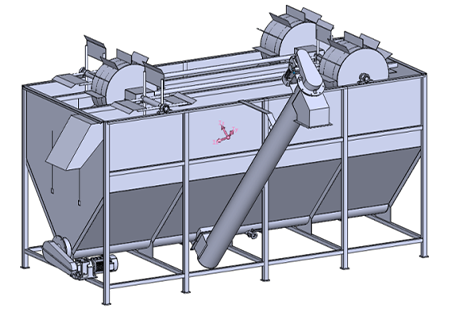

Trommel

The material can be turned and rolled irregularly in the screen cylinder to remove small debris such as sediment -

Sink Float Tank

The crushed material is rinsed and separated from the ups and downs, the floating material is discharged,and the submerged material enters the bag -

Friction Washing Machine

It can remove the external impurities before the PET bottle çrushing as much as possible. -

High-efficiency Centrifugal Dehydrator

The main body is designed with fasten style installation,mesh with easy dismount and replacement ability at the same time,It has a self-cleaning mechanism and anti-plugging feature to keep the unit at a consistent high performance. -

High -efficient Label Remover

Remove the label from the PET bottles. The rate of removal can be controlled by adjusting the gap between the calibration knife and the moving knife,After the removal of the label by this machine, more than 92% of the label paper can be peeled off. -

Zig-zag Separator

It can effectively separate the dust in the flakes, small plastic labels or film, The label aspirator separates the label and fine impurities from the flakes by the negative pressure which generated by blower. -

Wet Grinder

It is capable for wet crushing which cause friction washing to flakes. Meanwhile,water flushing cool down crush blades,and reduce crusher chamber temperature and blade abrasion, it reduces powder and loss of flakes.

Production line features:

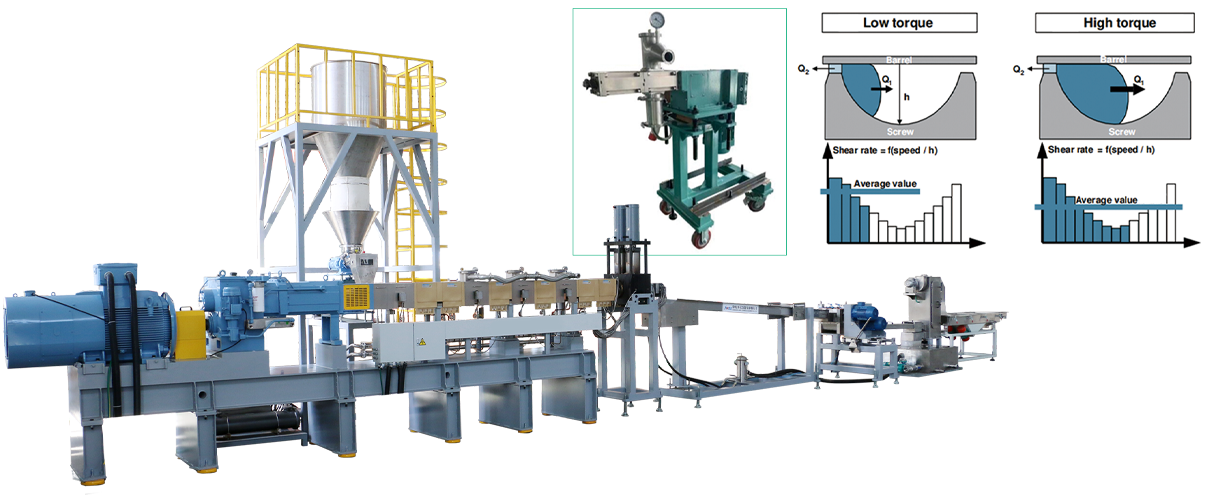

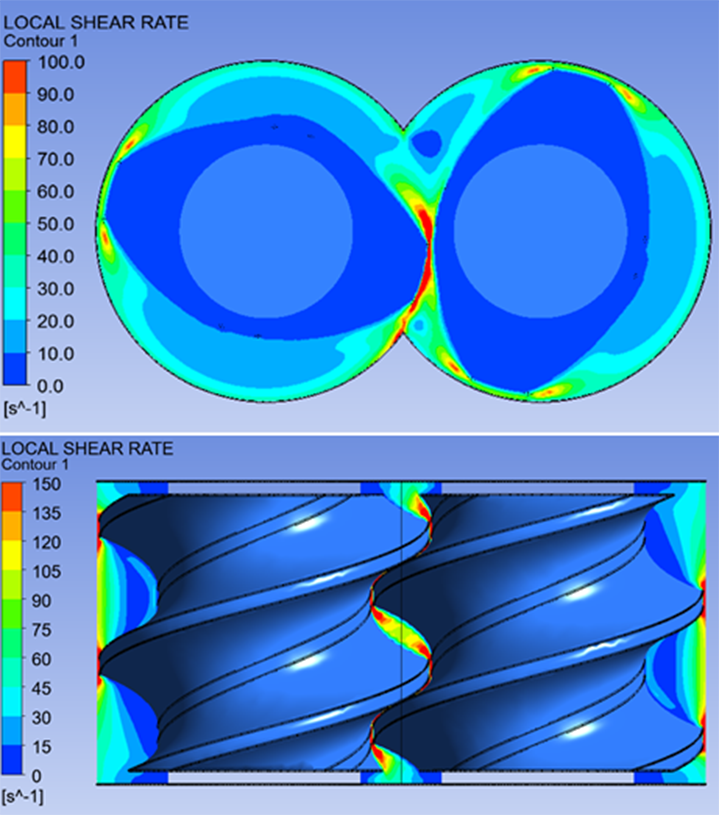

There are strict requirements on the viscosity of granules during the recycling of PET bottle

flakes, Our company adopts advanced strand cutting In water pelletizing lines for this market

ensures that PET granules can reach food grade.

Super high torque gearbox, stable performance high efficiency and energy saving.

Low speed and small shear. The granules produced are uniform and capacity is high,

Equipped with vacuum exhaust and side exhaust system to effectively remove moisture and

impurities in PET materials and improve material performance.

High-efficiency filtration system which ls for filtering dirty Impurities In raw materials, make

granules meet the requirements of food grade.

High automation, simple operation and convenient maintenance.

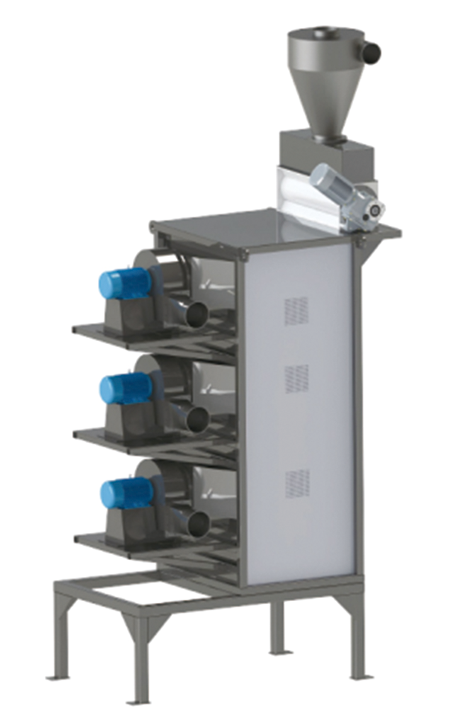

Solid state poly condensation - SSP

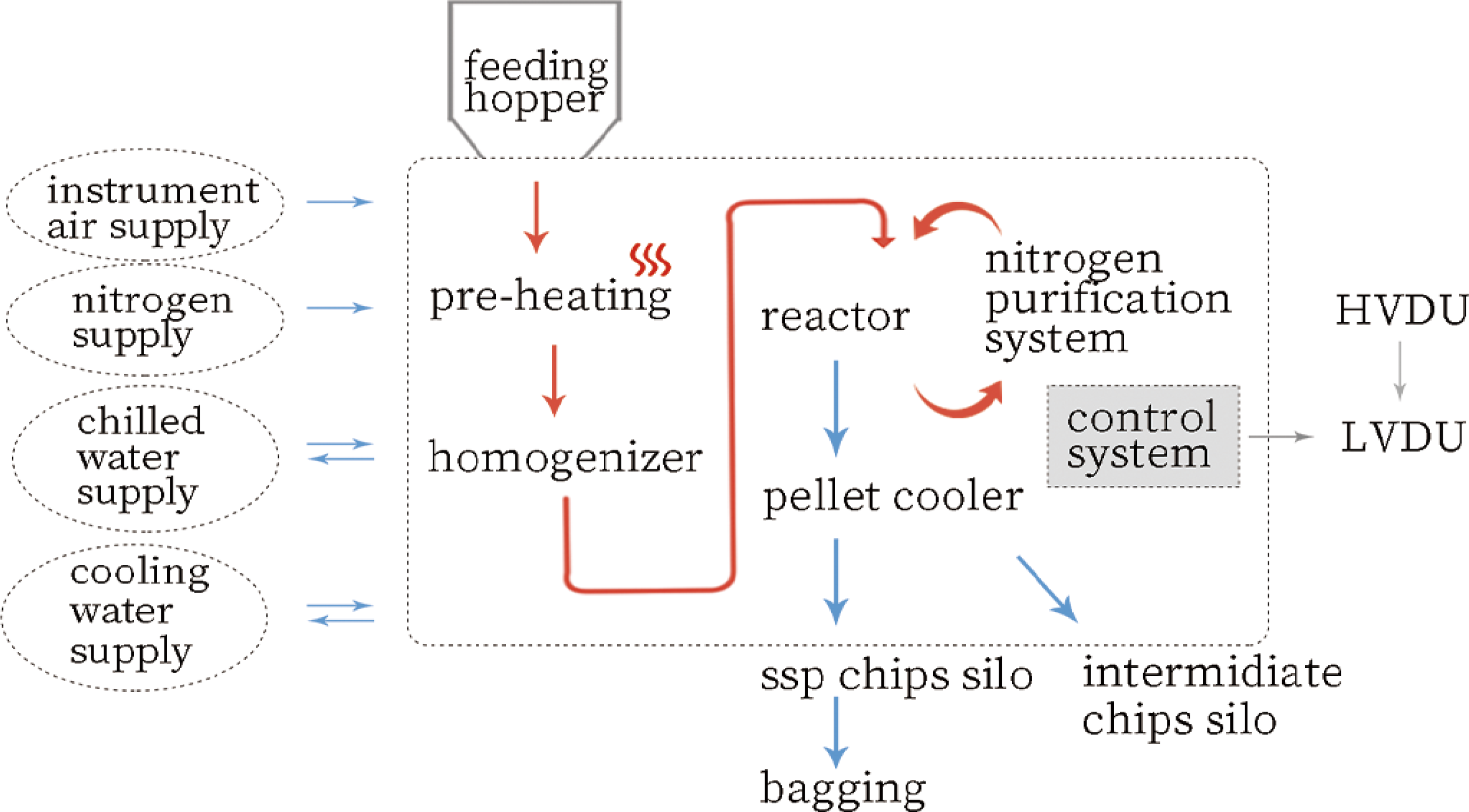

rPET CHIPS SSP PROCESS FLOW

Process description:

This plant in the proposal is a continuous SSP system, which make the recycled granules

condensation polymerization through preheating & polymerization process.

It improves viscosity to required one, and also removing the acetaldehyde, glycol and oligomers,

etc in the re-action to achieve the technical indexes for high IV granules, in order to prevent

granules oxidation in high temperature, main process are under the protect of nitrogen which can

be used circulated through purification.

This system is composed by preheating system, conveying system for hot granules, Solid state

Poly-condensation system,pellet cooling system, nitrogen purification system, product conveying

system, jumbo bag packing and control system.

Advantages of SSP system

Excellent V control technology

Nice chip color

Low content of the acetaldehyde

High capacity and low consumption

No chip damages

No mechanical moving parts, No dust

Uniform chip resident time during different process phases- Compact equipment structure

rPET granules requiremnet

SSP granules data

This video introduces recycling materials technology solutions. Polynk can provide a whole solution. Any interests, please send email to alex@polynk.com

recycling materials technology solutions

-

PP/PE bottles

-

PP/PE flakes

-

PP/PE pellets

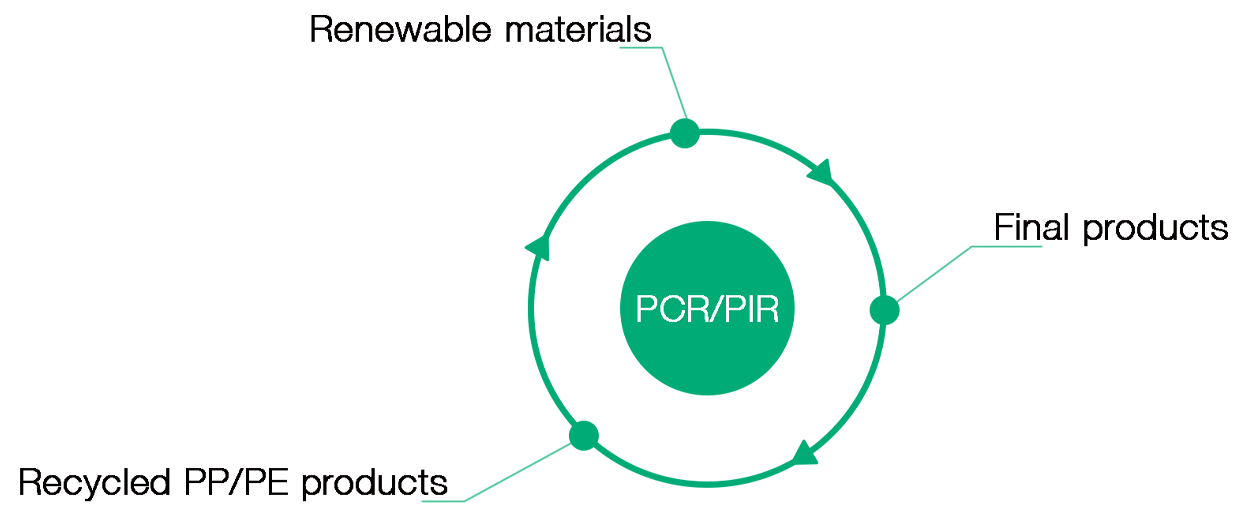

PP/PE pellets application:

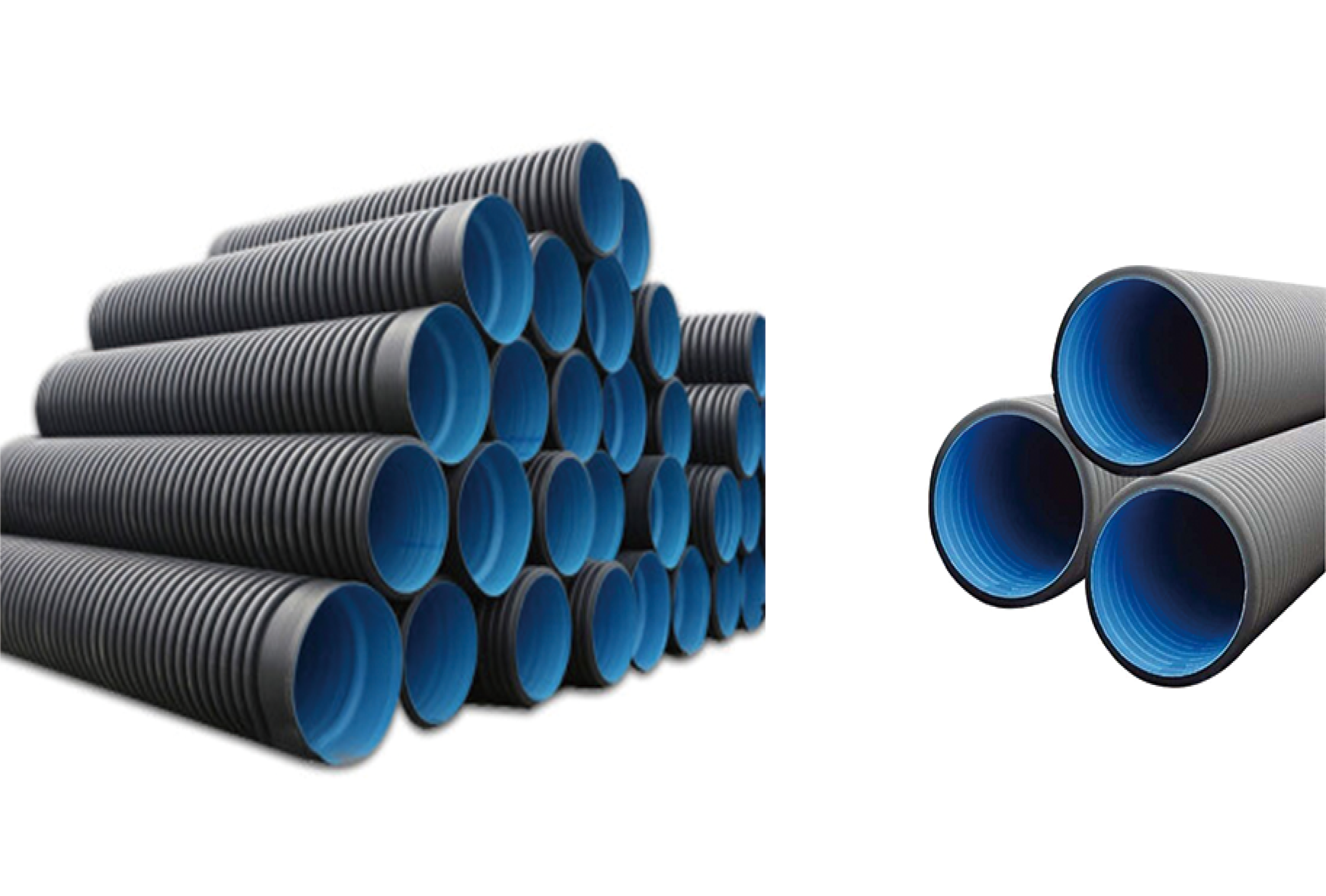

The PP/PE plastic washing line is mainly used to recycle plastic products used in daily life so

called "PCR".

Through the selecting, crushing, washing and pelletizing, the clean and reusable materials are

obtained for down-stream for various plastic products, such as building templates, corrugated

pipes, hollow pallets, photovoltaic floating barrels, etc. which can realize "PIR".

This way not only reduces carbon dioxide emissions, but also reduces energy consumption.

-

Building templates

-

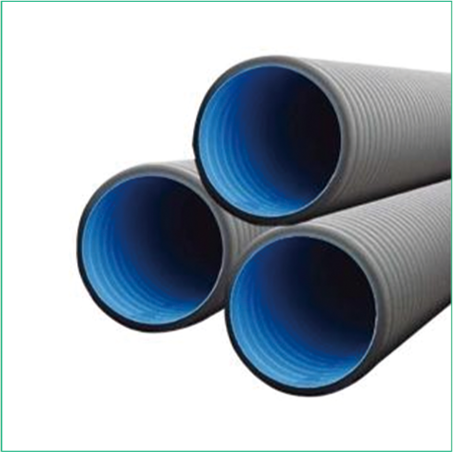

Corrugated pipes

-

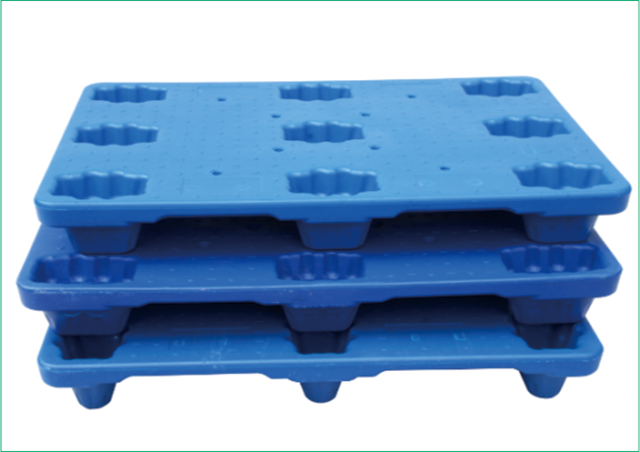

Hollow pallets

-

Photovoltaic floating barrels

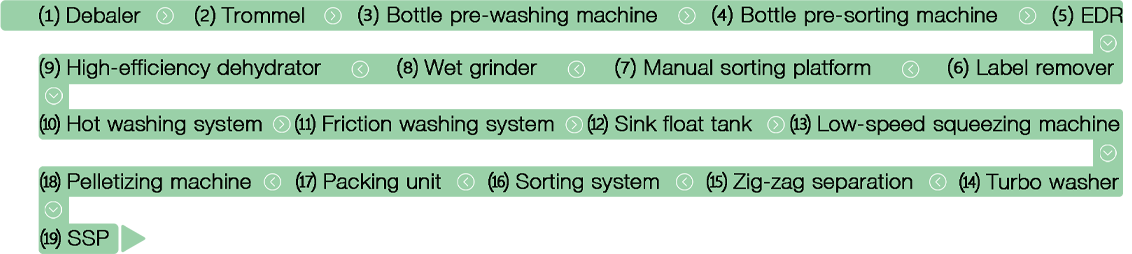

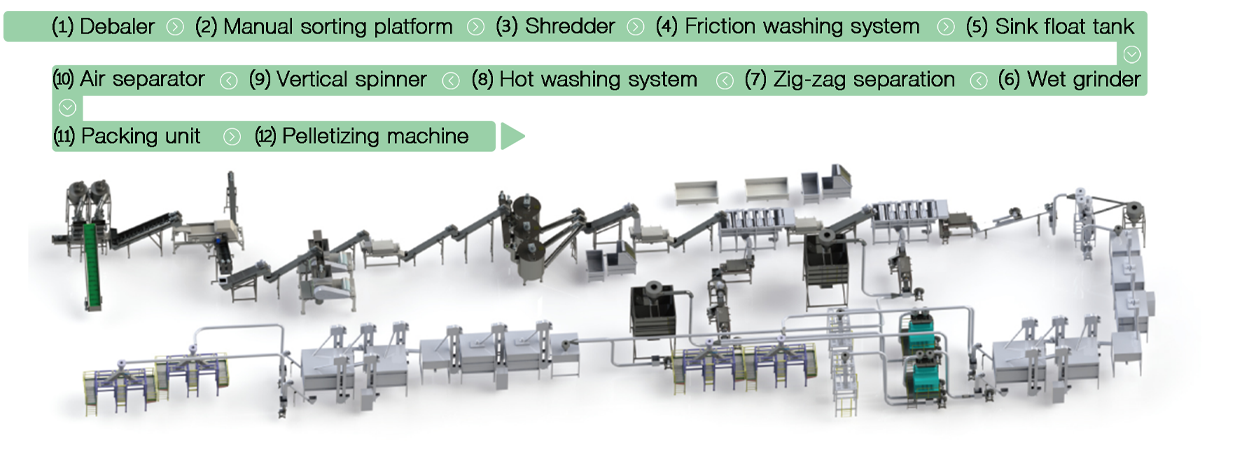

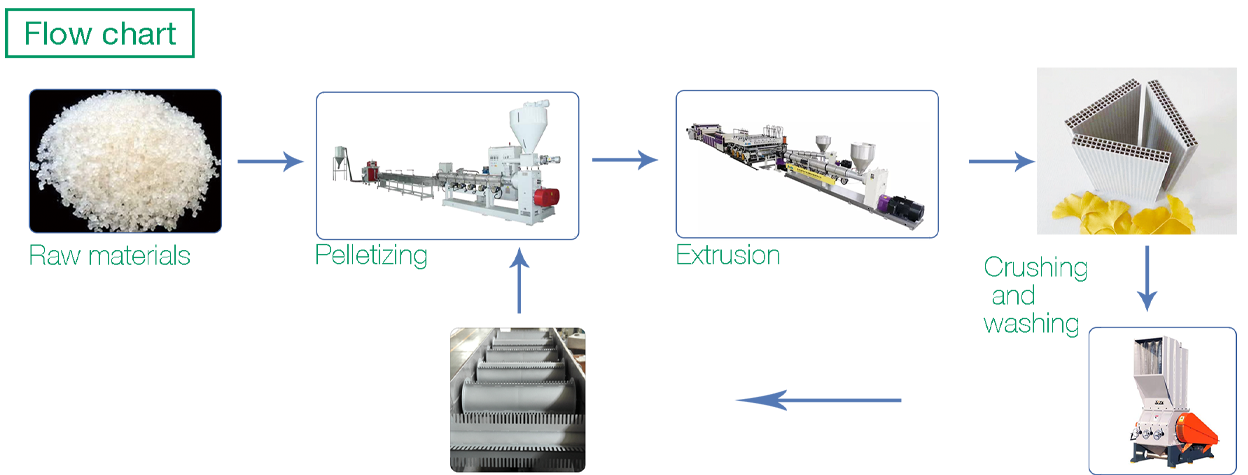

Recycling Process Flowchart

Main technical parameters

For the total power, 70% is actual power while 30% is power margin.

How to remove woods from PP/PE flakes?

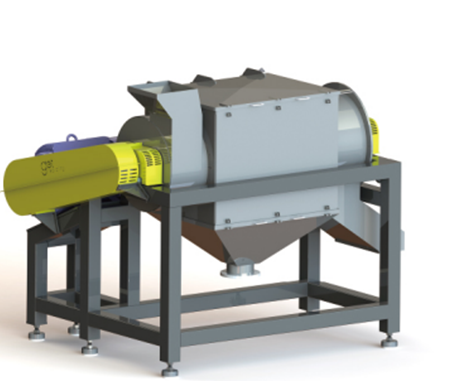

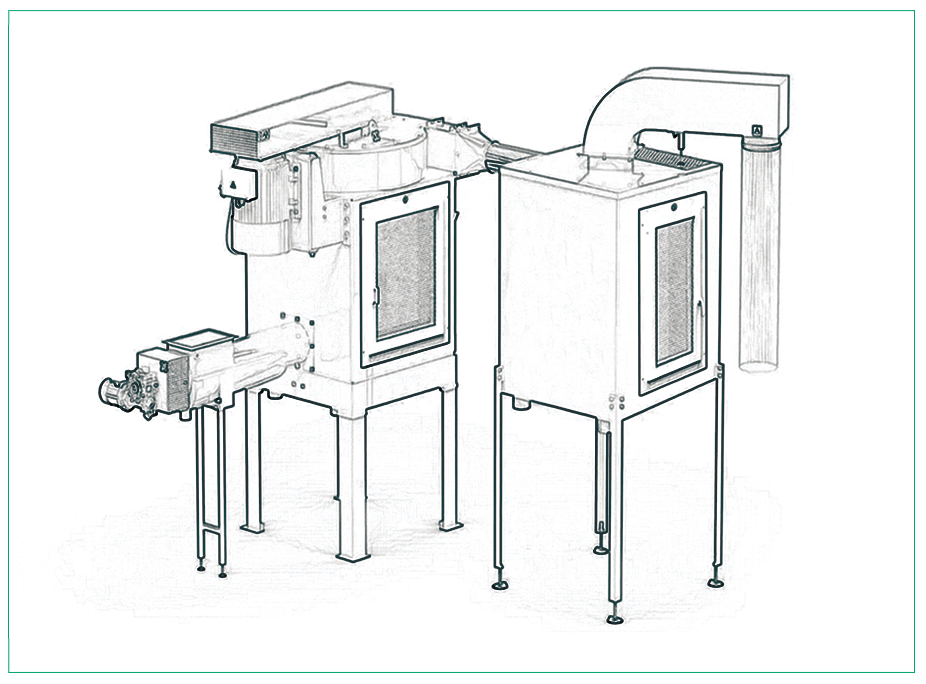

The dynamic centrifuge

The dynamic centrifuge can be used to centrifugally squeeze the crushed wood from HDPE water and

prepare them for the drying stage.

From the centrifuge, the product is fed by a pneumatic transport system to the accumulator

cyclone.

Contaminants washed with HDPE crushed grains settle on the bottom and grids of centrifuges. The

resulting sediment is removed from all baths and centrifuges periodically when they are

completely drained.

Function

The dynamic centrifuge is a centrifugal plastic washer used in different applications to wash,

dry and separate many flexible or rigid materials.

The centrifugal effect of the plastic waste washing machine is based on mechanical friction

combined with the use of a big quantity of water in order to guarantee a very good cleaning

effect of the product.

For less contaminated materials the plastic washing machine can be used as "dry separator .

The dynamic centrifuge is also very efficient in the separation of the super absorbent polymer

(SAP) from cellulose in the recovery process of absorbent products.

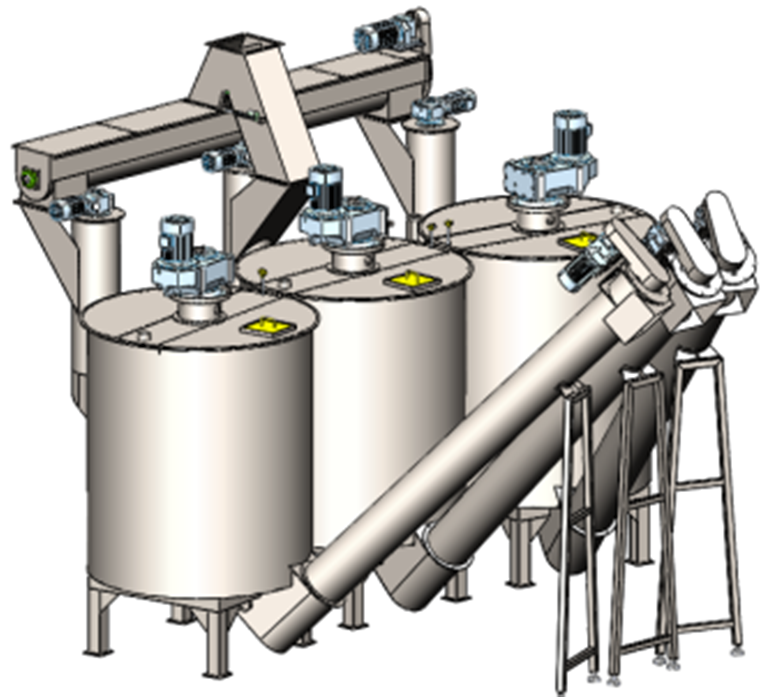

Main functional machine introduction

-

Sink Float Tank

The crushed material is rinsed and separated from the ups and downs, the floating material is discharged,and the submerged material enters the bag -

Wet Grinder

It is capable for wet crushing which cause friction washing to flakes. Meanwhile,water flushing cool down crush blades,and reduce crusher chamber temperature and blade abrasion, it reduces powder and loss of flakes. -

Zig-zag Separator

It can effectively separate the dust in the flakes, small plastic label sorfilm, The label aspirator separates the label and fine impurities from the flakes by the negative pressure which generated by blower. -

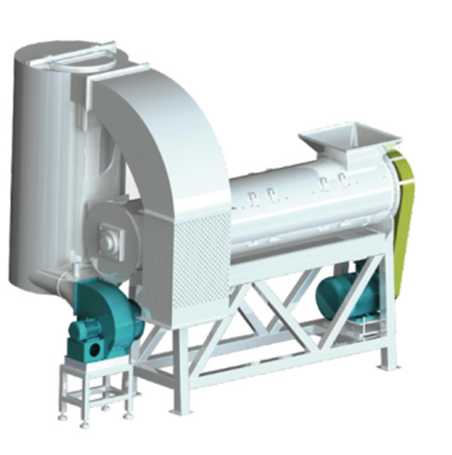

Hot washing system

It can be used for washing PP&PE flakes and removing glue and oil on the surface of flakes by hot caustic soda water.

For more information, please send email to alex@polynk.com

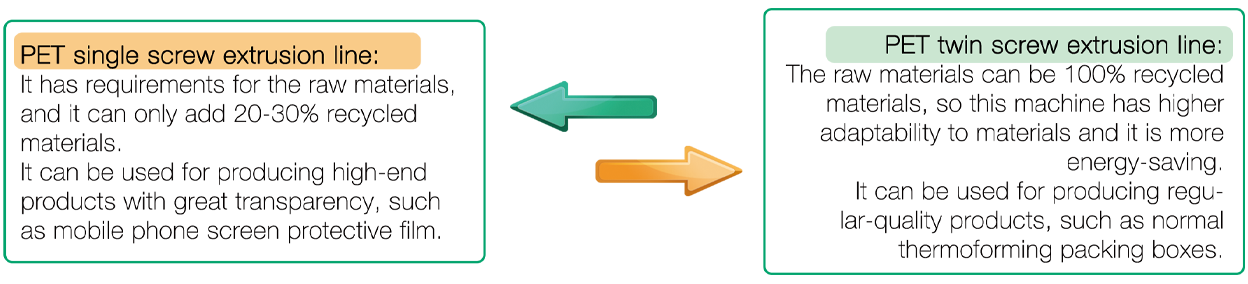

The PET parallel twin screw sheet extrusion line is equipped with degassing system, and no need drying unit. The extrusion line has the properties of low energy consumption, simple production process and easy maintenance.The segmented screw structure can reduce the viscosity loss of PET resin. The sheet is widely used for therm-forming packaging industry.

Main Technical Parameters

PET single screw dryer-free vented sheet extrusion line

The PET single screw vented sheet extrusion line is energy-saving. The structure of the screw can minimizes the viscosity drop of the PET resin and maintains the original toughness of the sheet. It can produce the high-transparency sheet,-such as the mobile phone screen protective film, which can fully meet the needs of the market.

This video shows the crushing and washing of PE film and PP woven bags. For more details, send email to alex@polynk.com

Super high torque gearbox, stable performance, high efficiency and energy saving.

Low speed and small shear, has small damage to raw materials, The granules produced are uniform

and capacity is high.

Equipped with vacuum exhaust and side exhaust system to effectively remove moisture and

impurities in PE materials and improve material performance ,

With laser filter, remove remaining impurities and unmelted polymer from the melt.

With latest Re Fresher technology, which greatly reduce low-volatile and high-molecular-weight

organic compounds in recycling pellets, reduce odors. This enables recycled materials to be used

in productions that are n direct contact with various foods.

-

Super high torque

-

Lasser filter

-

Side exhaust system

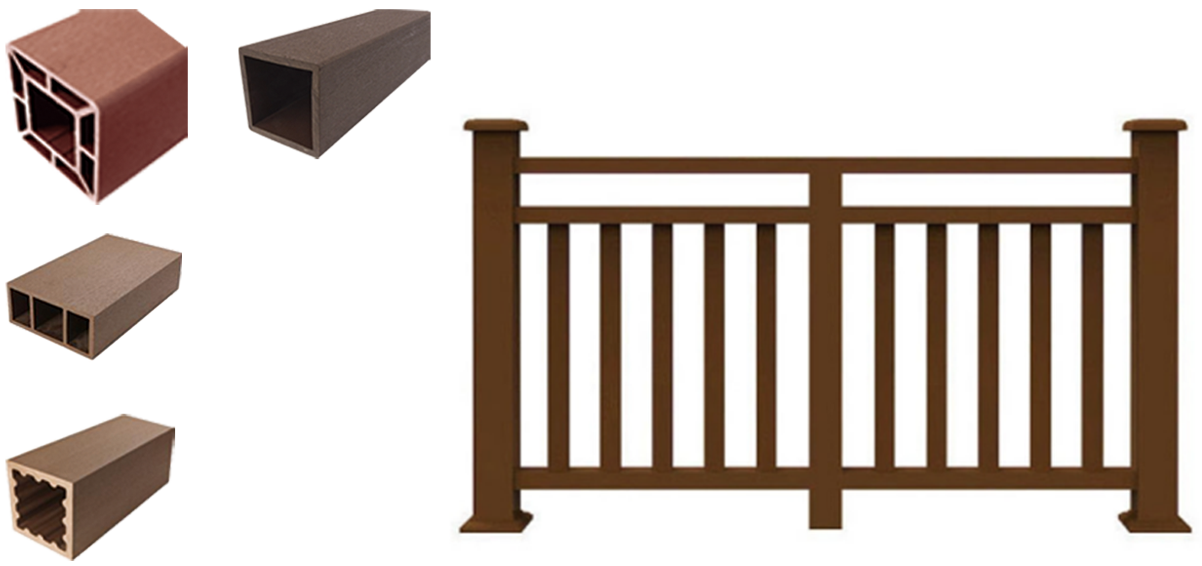

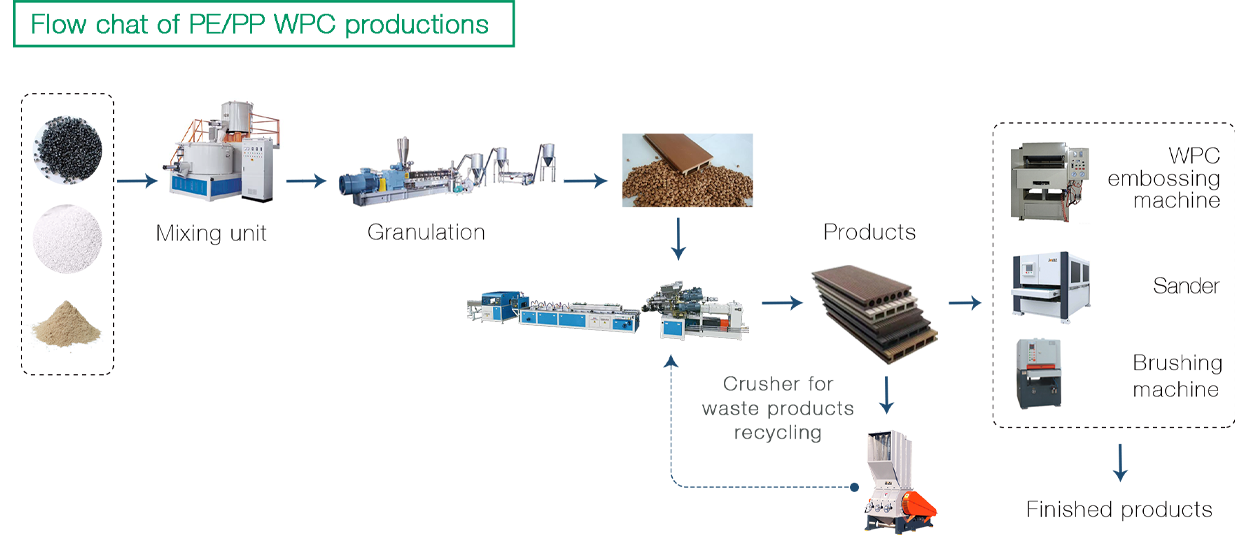

WPC(PE&PP) Wood-Plastic Floor is that the wood-plastic composite materials complete in different equipment of mixing, from play, extruding products, mixing the raw material in a certain formula, forming wood-plastic particles in the middle, and then squeezing out products. For more information, please send email to alex@polynk.com

Advantages of PE/PP WPC products:

1.Waterproof,moisture proof,insect proof,termiiteproof

2.Replace wood with plastic,save wood materiatsand protect the environment

3.Recyclable,saving row materials costs

4.With various colors for customents to choose

5.High fire resistance,fireproof grade reaches B1,can effectively fiame retardant

Application for PE/PP WPC products:

Wood plastic composites:

PE recycling materials physical properties

Formula for reference:

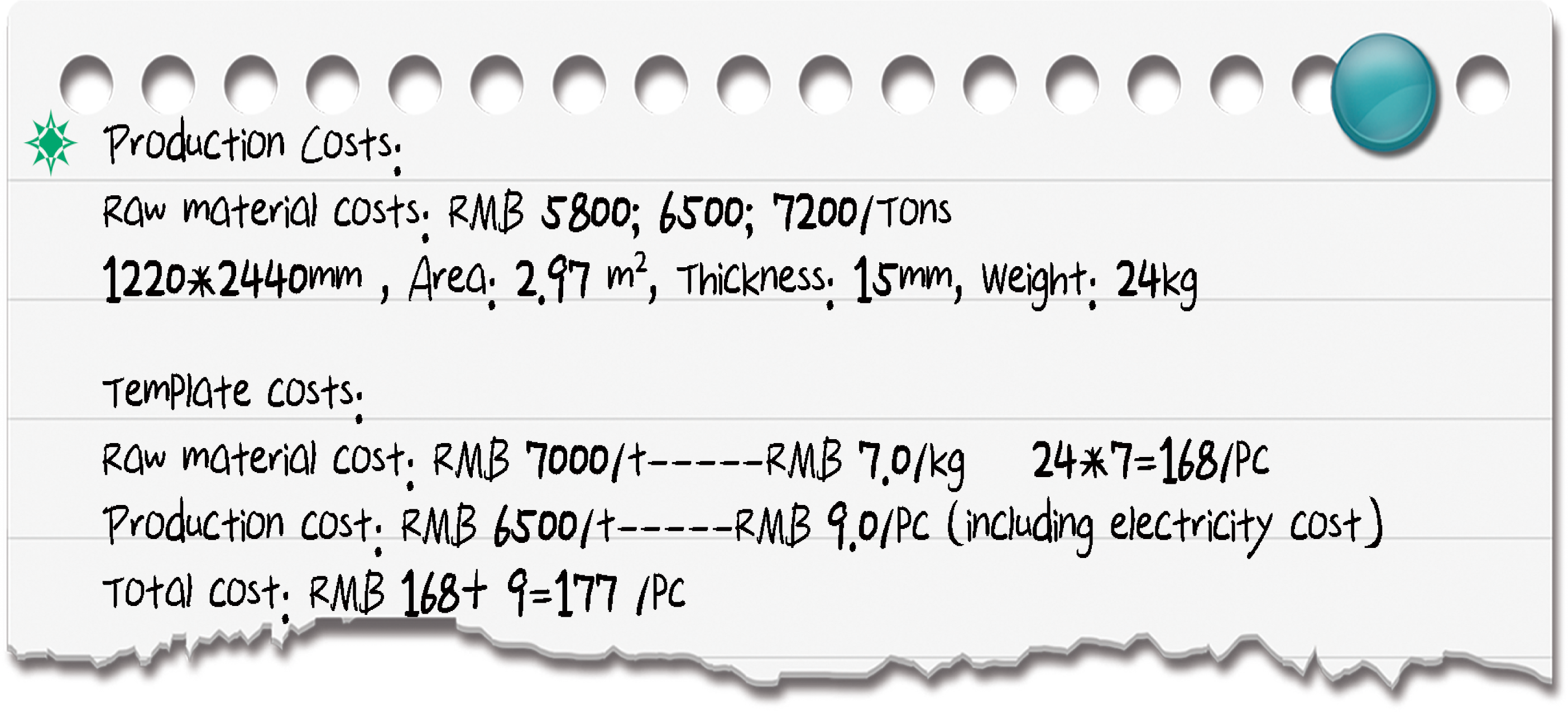

Mixing raw materials costs:RMB 3000-3500/Ton

Processing costs:RMB 700-1000/Ton

(including water, electricity, labor)

PE WPC extrusion line

Machine list.

Extruder--Co-extruder

(adding ASA Co-extrusion layer on surface)--Molds-- Embossing machine

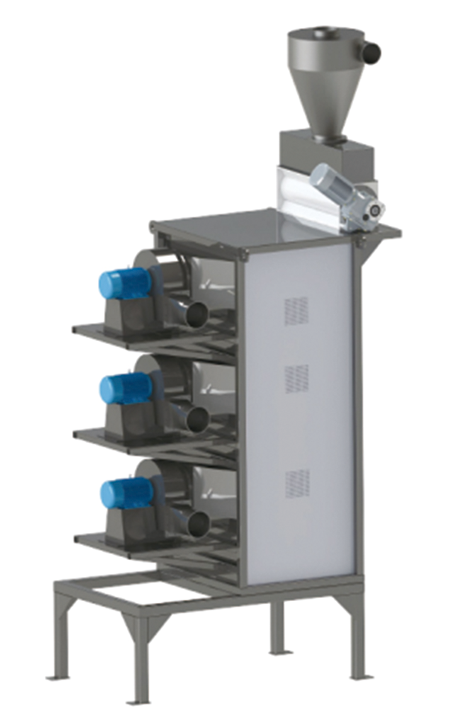

PE WPC granules making machines

Mainly used for granulation of wood powder or filler with raw materials like PVC, PP and PE The auxiliary machine adopts wind-blowing collecting and cooling system, has the characteristics of high automation and great production efficiency

Visiting WPC raw materials company in Qingdao, one of the biggest manufacturer for WPC materials in China, WPC raw material is short for wood plastic composite(compound) material, for more details, send email to alex@polynk.com

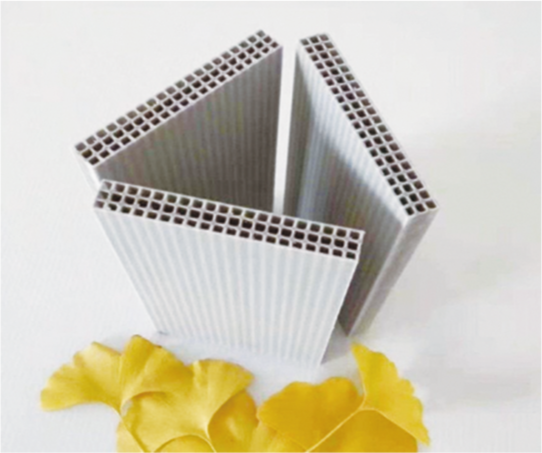

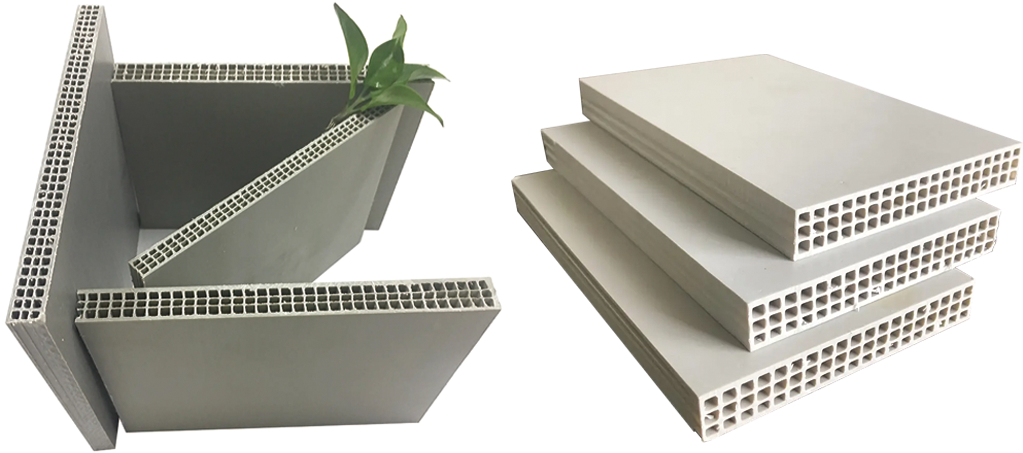

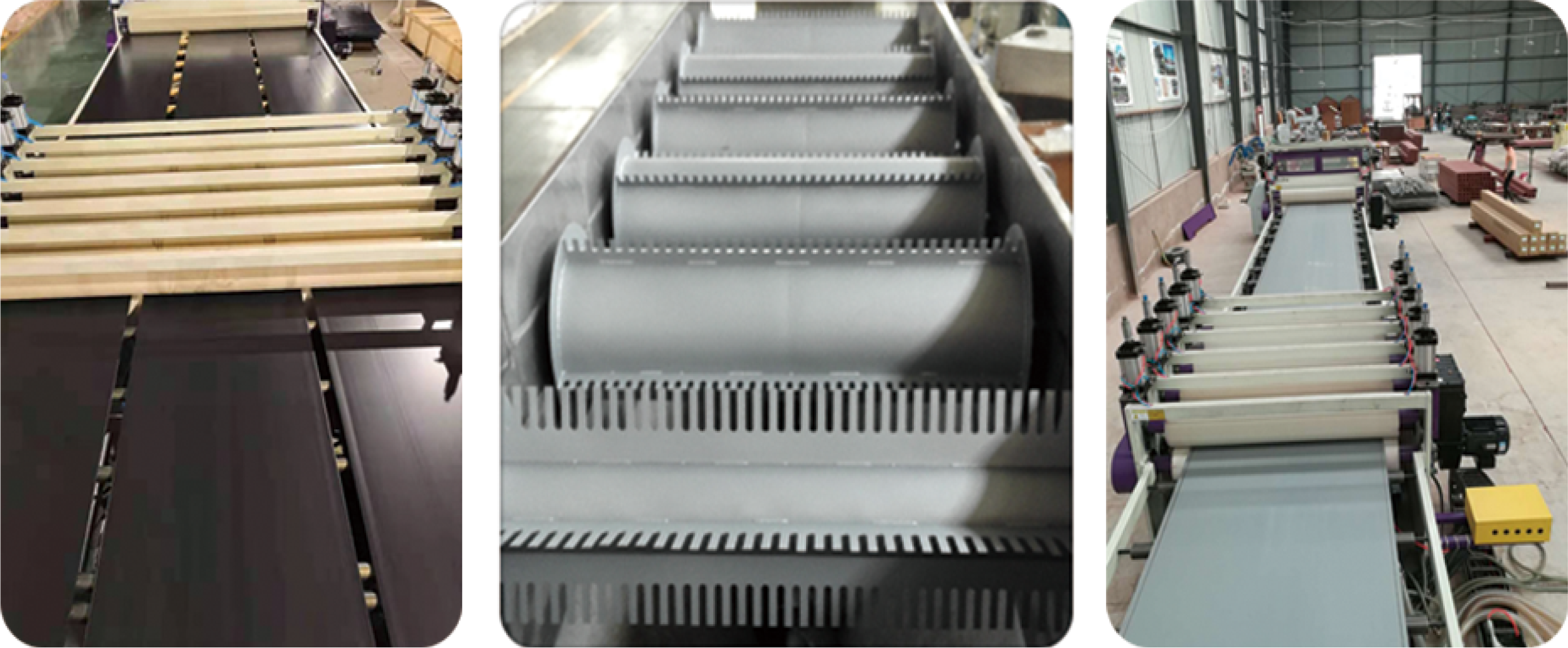

hollow building template from recycled material, totally environmental friendly, represents the future, make the earth a green place. for more details, send email to alex@polynk.com

Advantages of PP hollow building templates compared with wood plates

Physical performance of PP building template

Technical parameters

Machine features:

1.Extrusion with exhaust structure, the water is discharged during plsicizing process to ensure

the surface quality of the products;

2.Through technical innovation of the mold, the two sides of templates are more strong;

3.Improve cutting structure, ensure no dust leaking for such hollow plate;

4.Low production energy consumption, 200 o 1 hour for a single machine production line; 230

°/hour for double-position line.

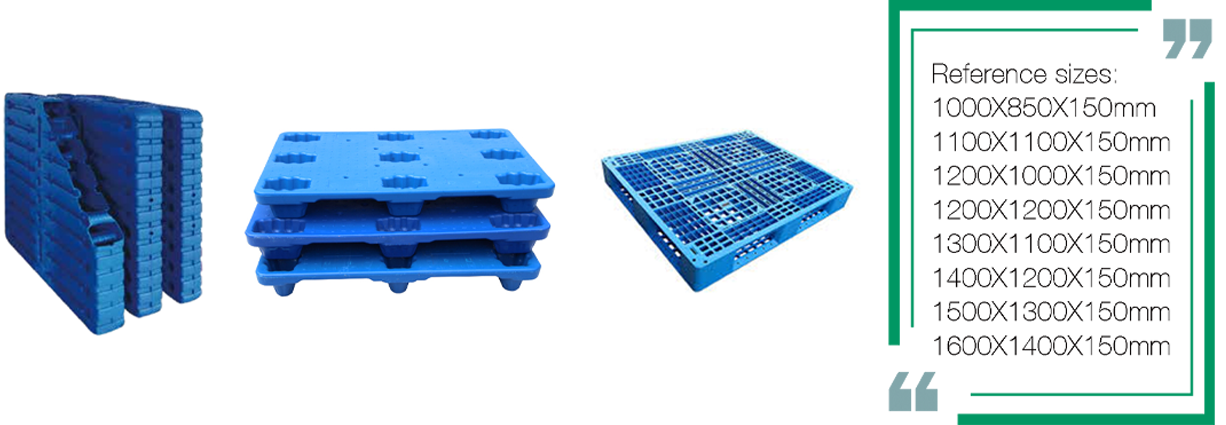

This production line is suitable for producing different kinds of pallet. For more information, please send email to alex@polynk.com

Application:

1.Double- side pallet:It is widely used in chemical, fertilizer, feed and other bagged

industries.

2 Nine-leggs pallets:It is widely used in medicine and food industries with strong turnover.

Advantages of blowing pallets:

-

Strong carrying capacity:

With a variety of sizes ,meet the needs of various material load-bearing capacity. -

Efficient operation:

It is convenient for forklift handling and can be inserted on all sides, which greatly improves the efficiency of warehousing and logistics -

Widely used for industry:

It is suitable for stacking in the warehouse and using it on all kinds of shelves,truck transportation, which is convenient for the containerization of materials. -

Safety anti-slip:

With non-slip rubber,ensure that the goods will not slip during transportation and avoid material and labor damage -

Low carbon and environmental-friendly:

Lightweight,Recyclable and cost saving

Difference between plastic pallets mady by blowing molding machines and injection molding machines

Raw materials requirements:

HDPE raw material: low pressure high density polyethylene;

Melting point: 130℃ Density : 0.941 -0.965g/m³;

Material costs:

Bad level: 100% recycling HDPE materials (MFI 0.8)+ 10% master batch, RMB 8000/t

Common level: HDPE granules (MFI 0.7) + 30% recycling materials+ 10% master batch, RMB 8770/t

Good level: HDPE granules + 10%-20% recycling materials+ 10% master batch, RMB 8880/t

Best level: 100% HDPE granules+ 10% master batch, RMB 9100/t

( the price is just for reference)

Acceptance criteria for plastic pallets

This video introduces the modular design for horizontal pressure water-cooled corrugated pipe production line. For more information, please send email to alex@polynk.com

This video shows the successful operation of 1000 mm DWC pipe extrusion machine in our foreign customers' factory. For more details, send email to alex@polynk.com

Horizontal-type pressure water cooling double wall corrugated pipe exturion line

Main Technical Parameters

Meter weight and line speed for different size of pipes

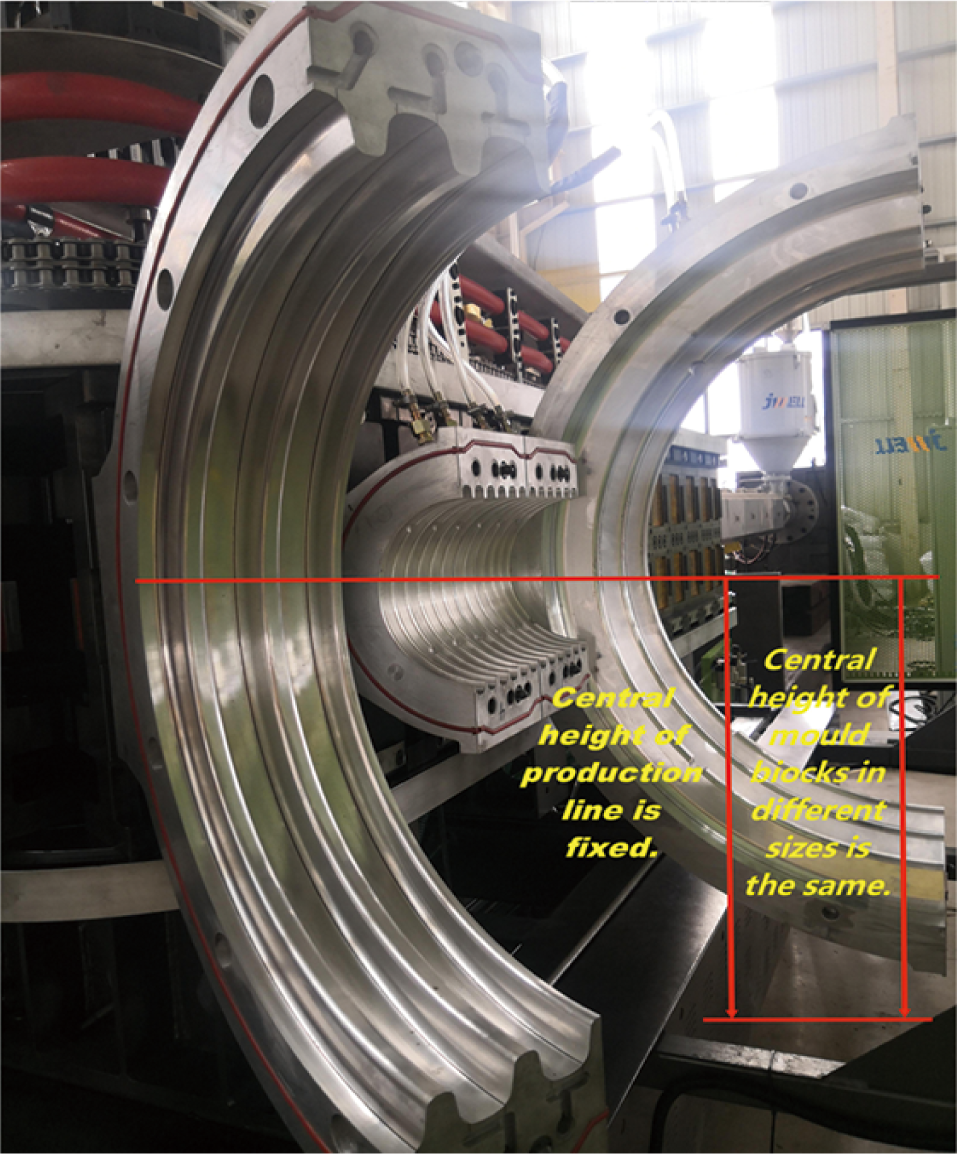

innovative technology

1.For the same ring stiffness(SN4/SN8. .), we can design the wave form according to the elastic

modulus to achieve the light-est weight, which can save costs.

2.The sliding base of forming machine is geared and equipped with large size needle roller

bearing,which improves the bearing capacity of the sliding base.

3.The center height of the forming machine is fixed, and there is no need to adjust it again

when changing model.

4.It adds a half-off unit, which can effectively avoid the flaring deformation of the pipes, and

improve the speed of the production line.

5.For the cooling water circulation system, the single roller chain is changed into the double

row roller chain, which makes the circulation more stable.

High speed energy-saving pipe extrusion line

-

Introduction:

The high-efficiency and energy- saving pipe extrusion рrоduсtіоn line can make pipes from Ф 16 to Ф3000mm.

It has the advantages of high output, low energy consumption, good melt homogeneity and long-term operation stability, The modular design scheme provides convenience for product serialization and versatility in the way to save raw materials and improve the automation.

Innovative technology