Home>Biodegradable products solutions>

-

Biodegradable bag

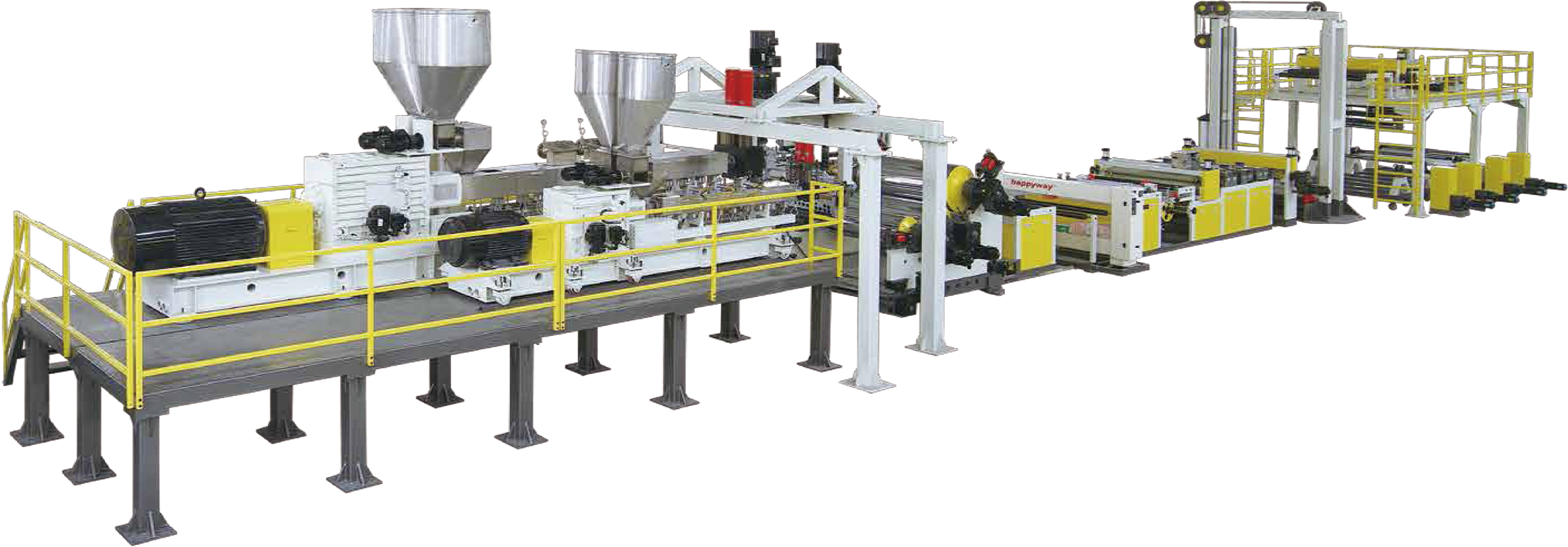

Testing of biodegradable film blowing machine in Jwell's factory. for more details, contact alex@polynk.com

For more information, please send email to alex@polynk.com

Fully degradable bag formula: Pl A+PBAT+ starch

PBAT has good toughness, but relatively soft. The strength of the bags made by PBAT material only is not good enough. But it can be mixed and modified with PLA to improve the strength, so that the bag has comprehensive good performance.Fully biodegradable film blowing machine (model 800)

This machine is suitable for the blowing of PLA, PBAT,corn starch degradable plastic film, and these materials are bio-based and environmentally friendly.

Special design of screw wind ring die for degradable materials,with feeding structure of eight-hole inflowing type, The mold runner has uniform material and no dead angle, which improves the fluidity of the melt in the mold, effectively solves the problem of material retention in the mold, and makes the films have good smooth and transparent surface.

High-speed computer gravure printing machine

This machine is suitable for printing biodegradable plastic bags and other packaging products. It is an ideal printing equipment for supermarket T-shirt bags, garbage bags;clothing bags and other packaging products.

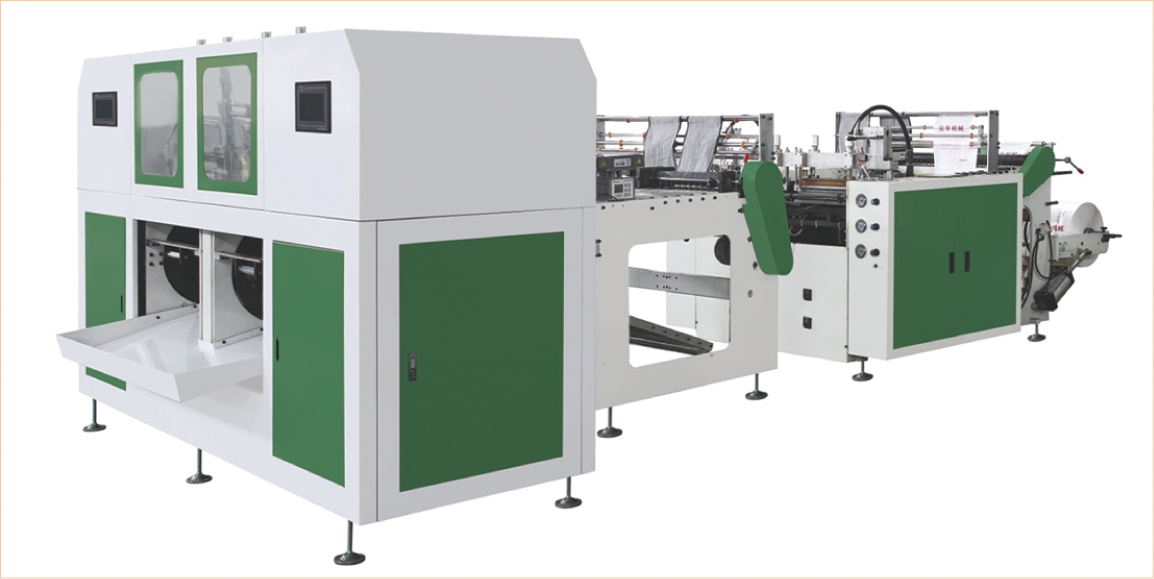

High-speed bag making machine

This machine is suitable for the production of heat-sealing and cold-cutting roll bags of PE and degradable material. Through the advanced computer control (software) system, the perforation of the toothed blade and the alternate operation of the sealing copper knife are completed synchronously, and the sealing is firm and beautiful.

The use of automatic roller changing auxiliary machine improves the production capacity and the product quality. It is an ideal equipment for the production of coreless flat-roll bags.、

Budget sheet for bag making production line

-

Fully degradable lunch box

Fully degradable lunch box formula: PL A+PBS+ADDITIVES

Just adding PLA, the softening temperature is 60"C, so it is necessary to add PBS to increase the softening temperature, up to 100C, which can be used for high-temperature product.PLA environmentally friendly degradable sheet production line

PLA environmentally friendly degradable sheet production line has the characteristics of low energy consumption, simple process and convenient equipment maintenance.

Multi component feeding device can reasonably control the proportion of new material,color master, etc.

The final products can be used in thermoforming and packaging fields.

Lunch box thermoforming machine

The maximum speed of this machine can reach 3 seconds/mold. It uses servo control system, coupled with the overall advanced supporting automation system. It can adapt to various sheets.

This machine has functions of heating, forming, punching, cutting, stacking and counting.

It can be widely used for PLA/PS/PET/PP/PVS/ABS and other plastic packaging materials.

Full degradation lunch box production line budget table

-

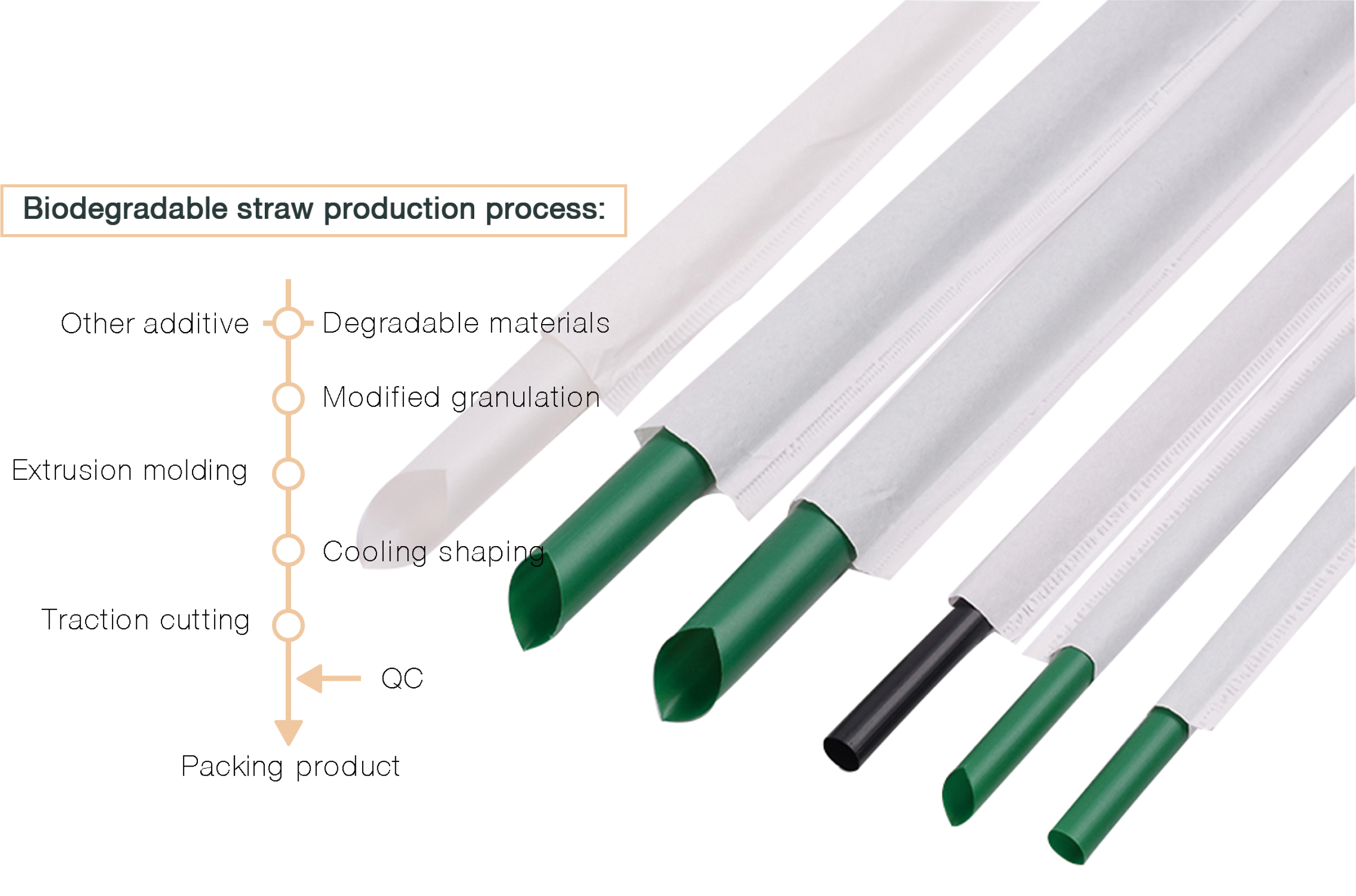

Biodegradable straw

This video introduces the PLA straw extrusion production line. For more information, please contact alex@polynk.com.

PLA straw pipe extrusion production line

JWS-PLA straw pipe extrusion line includesJWS65/28 efficient single screw extruder,mold, cooling water tank, traction cutting ma-chine, conveying and collecting device.

The extruder screw adopts 38CrMoAl material and nitriding treatment.

Screw UD; 28:1 power 30KW

-

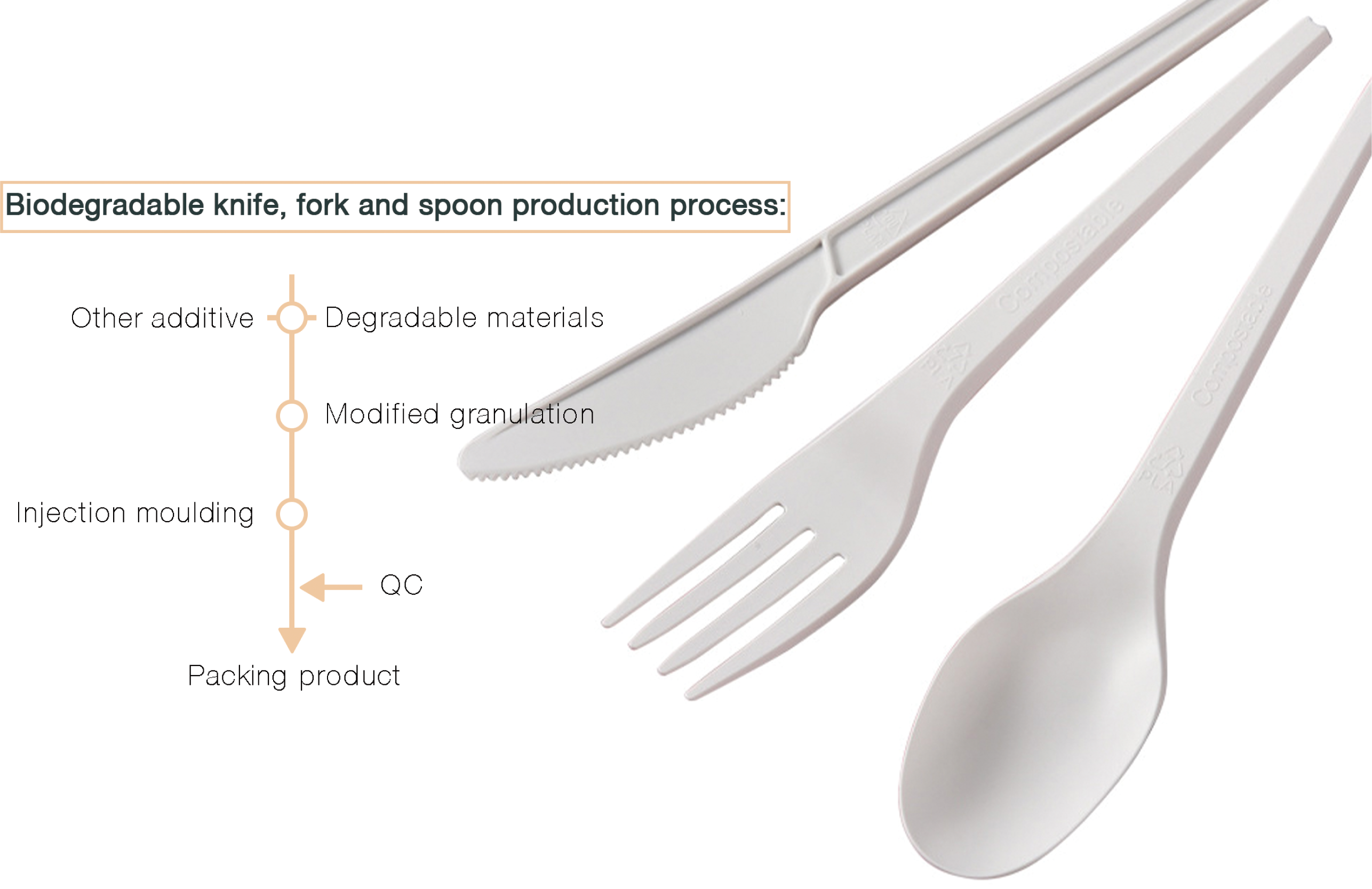

Biodegradable knife, fork and spoon

PLA straw pipe extrusion production line

The optimally designed injection unit provides higher precision and higher stability. The LD of The screw is more reasonable and the plasticizing abilities stronger. The special-designed screw can ensure the optimization of product quality.

Integral guide rod seat novel and beautiful, strong and reliable, injection faster, more stable, more tightly.

Modular design, fully meet the requirements of personalized processing technology, to provide customers with more choices.

-

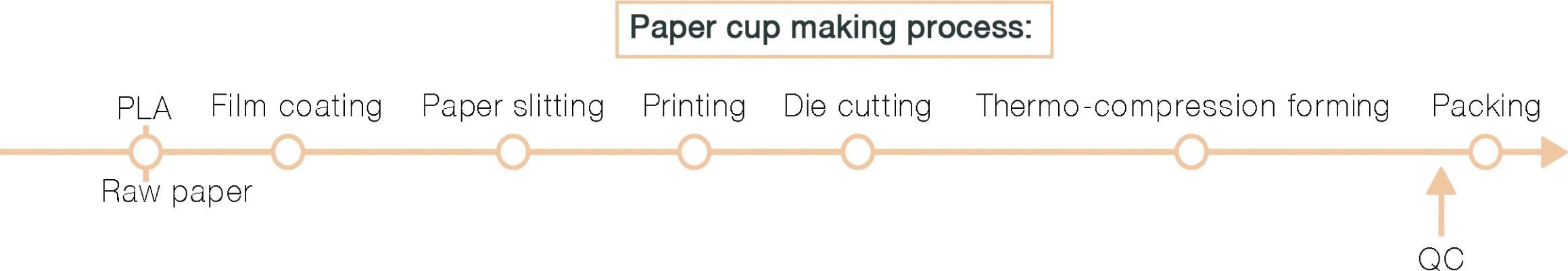

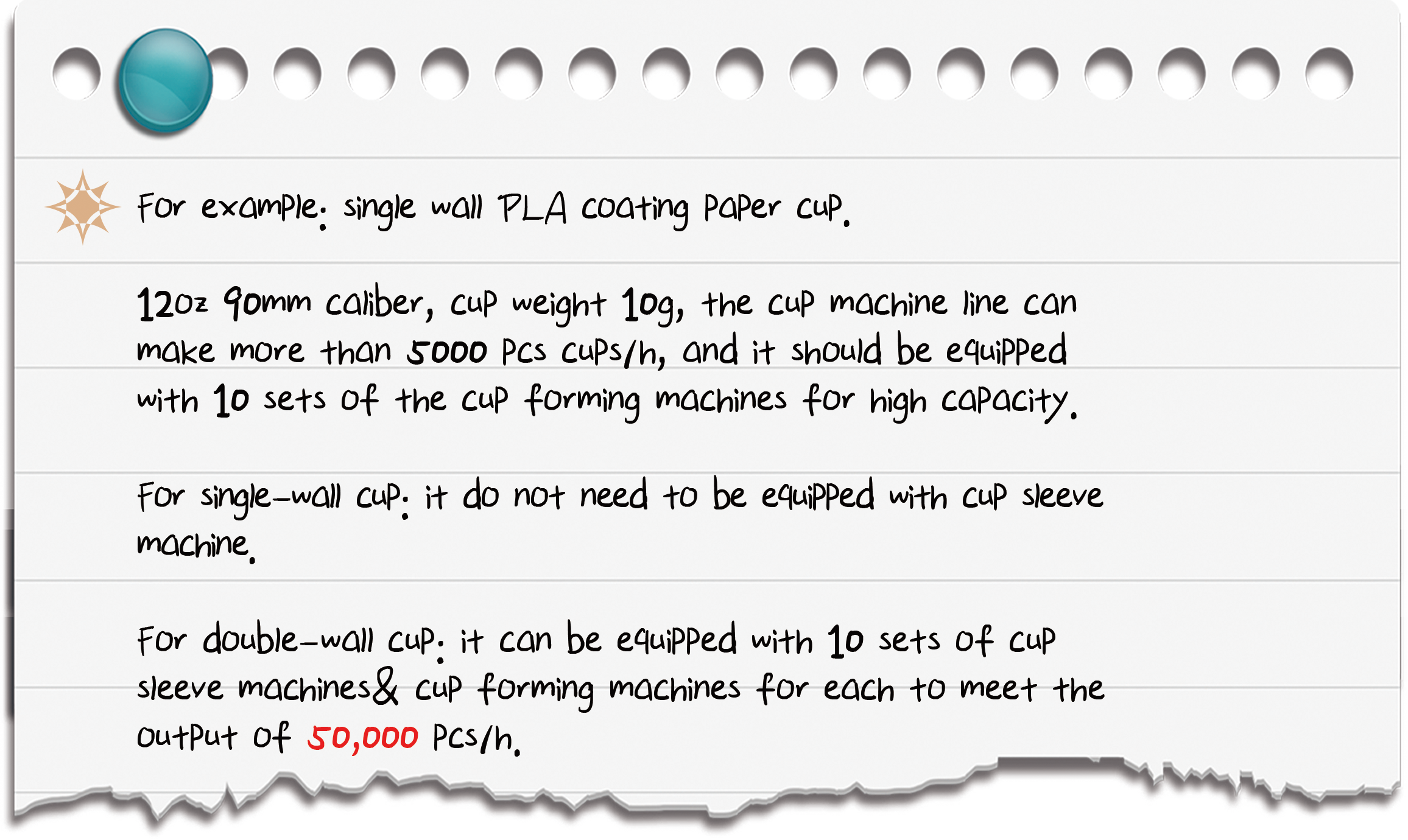

Paper cup coated with PLA

Paper cup production line related machines:Lamination machine

Application: It can be used for paper-plastic composite, plastic

composite, aluminum-plastic composite, non-woven aluminum film, paper aluminum-plastic composite, etc.

It is widely used in food packaging, drug packaging, shoe materials, luggage materials and other industries and fields.

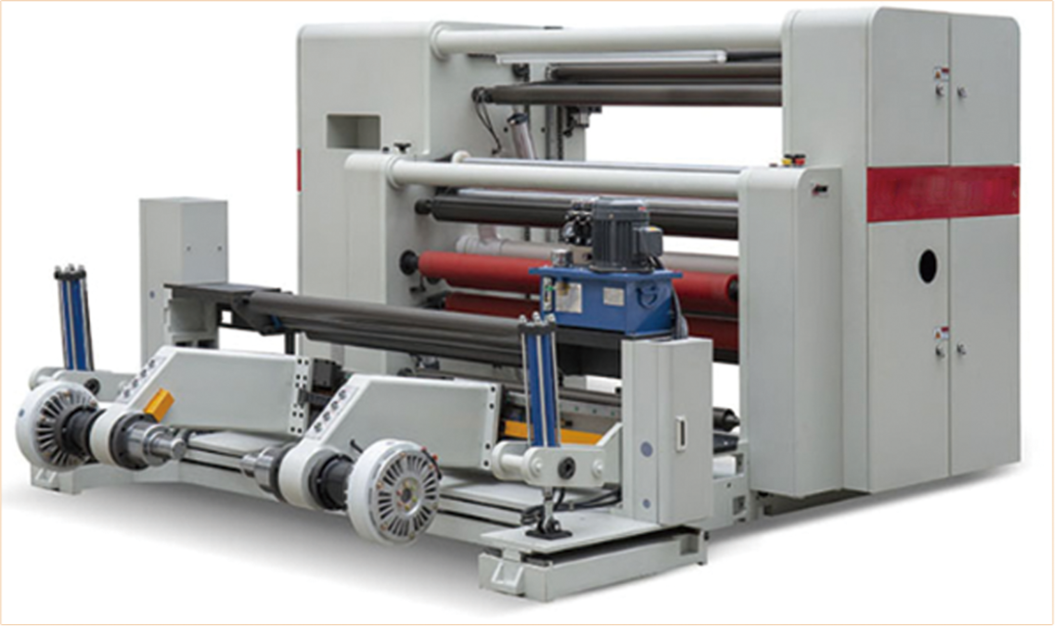

The parameters of the screw edge, compression ratio and distribution of each section were redesigned, and the coating layer was extruded from the die head of the extruder. The coating layer ran through the flat extension channel of the die lip, and was compounded with the base material in the bonding area.Slitting machine

Features: This machine is suitable for slitting various large coils, such as slitting and rewinding of cellophane, bill paper, double-sided tape, PVC, OPP, PET and other coils.

Printing machine

1. Adopt reticulated ink transfer;

2. Unwinding and rewinding are controlled by toner brake and clutch;

3. Each printing unit adopts 360-degree circumferential plate adjustment;

4. The ink can be automatically disengaged when parking and run at low speed to prevent the ink from drying out;

5. The main motor adopts imported variable frequency step less speed regulation;

6. Feed the paper from the tube material. Correcting, corona,printing, automatic infrared drying, winding once completed.

Die cutting machine

Advantages: Fully automatic reel high-speed flat die-cutting machine is a professional equipment for die-cutting, creasing,embossing coated paper, white cardboard,kraft paper and other paper, suitable for paper cups, cartons, medicine boxes,handbags, etc. All paper packaging products.

High speed double wall cup machine

Function: It is used to form the outer-sleeve for paper cups, and paper bowls.

It adopts the microcomputer system and runs a multiple stations with two turning plates, and makes cups with hollow double wall, which can separate from the heat, and safe for holding in hand.

It can match with the paper cup forming machine to form the double wall cup fully automatically.

Paper cup forming machine

Features: Automatic paper cup forming machine is the ideal equipment for producing beverage paper cup, tea paper cup,coffee paper cup, advertising paper cup and market paper cup, ice cream paper cup or other disposable cone shaped food paper container.

This machine is easy to operate, stable performance, small occupation area, high benefit.

Budget for PLA coating paper cup making line

-

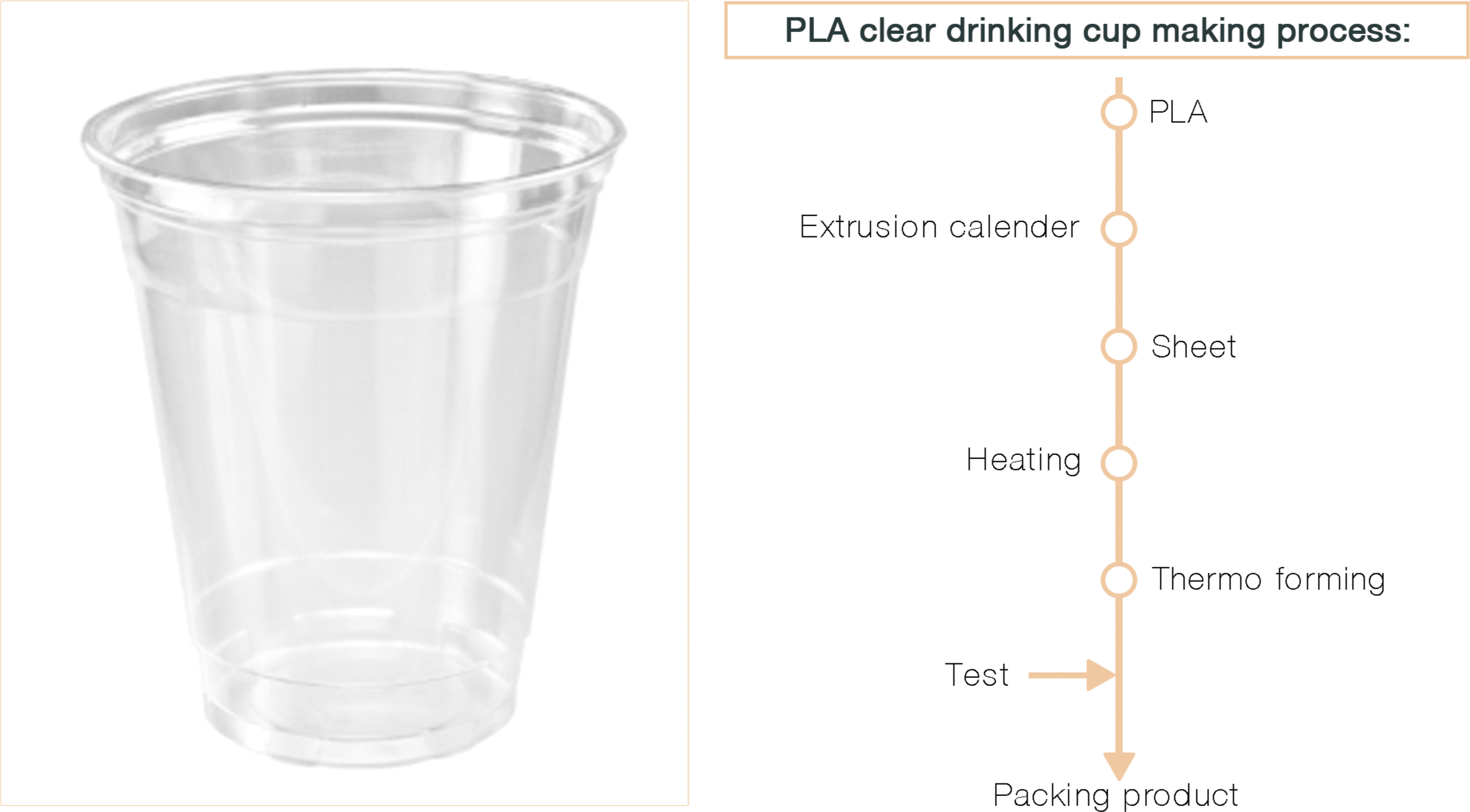

PLA clear drinking cup

PLA sheet extrusion line for PLA cup

Feature: PLA environmental degradable plate production line has the characteristics of low energy consumption, simple process and convenient equipment maintenance.

Multi component feeding device can reasonably control the proportion of new material, color master, etc.

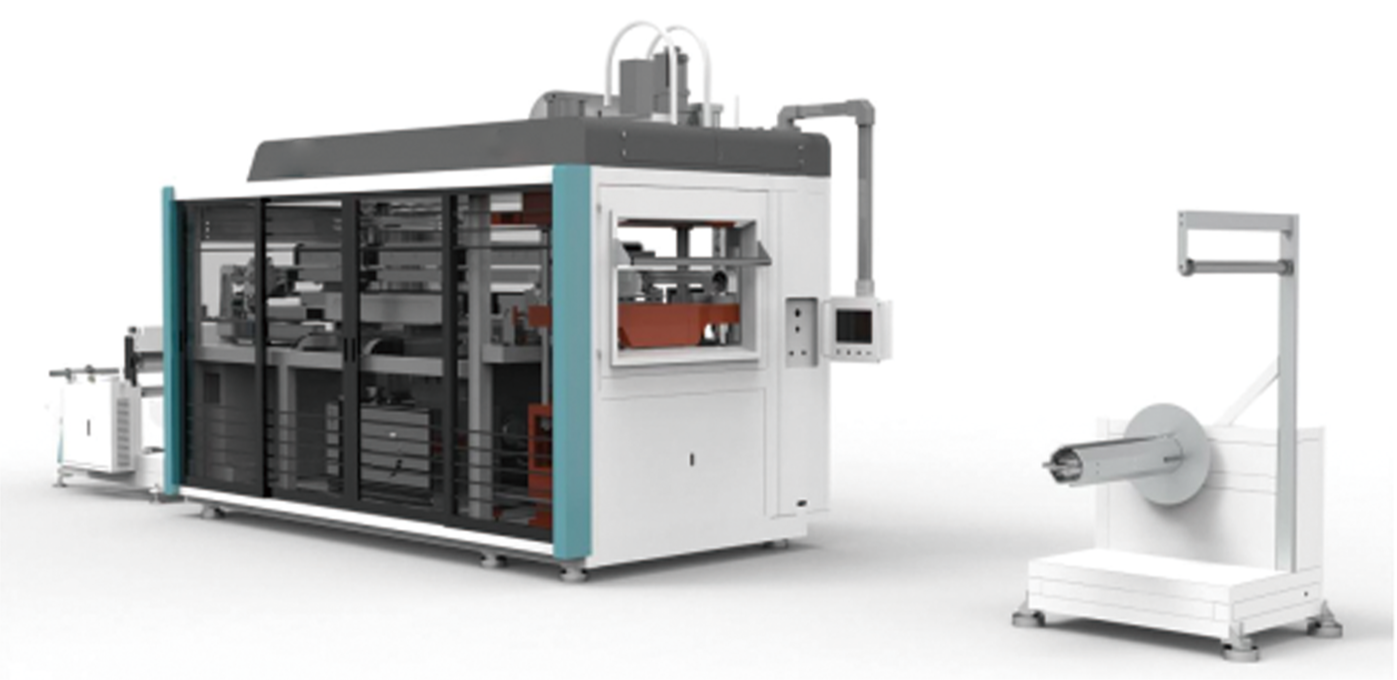

The sheet material produced can be used in blister printing and packaging fields.Automatic hydraulic four- pillar plastic thermoforming machine (cup machine)

Application: This series is mainly used to produce all kinds of disposable plastic cups, such as drinking cups,jelly cups, yogurt cups, flower POTS, disposable bowls,LIDS, plates, trays and other plastic products.

Automatic cup stacking machine

Application:

Automatic cup stacking machine is an assistant cup overlap-ping fitting for cup making machine.

It uses the machine transporting fitting and the structure of the cup, transports the cup after being produced by the cup making machine to the appointed cup overlapping part to overlap the cups, the height of the cups being overlapped can be adjusted to control the number of the cups according to the requirement.

Automatic cup stacking machine

Budget for PLA clear cup making line