Home>Biodegradable products solutions>

-

Why do we use Biodegradable plastics?

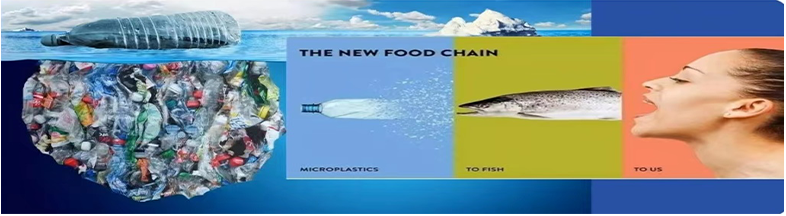

Traditional plastics are abandoned in the sea after use, causing pollution to sea water and fish, and finally harming ourselves .

Therefore, biodegradable plastics are needed to replace plastics, which degrade to carbon dioxide and water in 2-3 months under certain composting conditions, making our life more healthy and friendly.

-

Why do biodegradable plastics need modified granulation?

1.In terms of mechanical properties.

Due to its soft nature and poor fluidity PBAT needs to be modified by blending with PLA.

PLA has high tensile strength and tensile modulus but its high hardness and poor toughness limit its application.

Using PLA as filler of PBAT can effectively improve the tensile properties of PBАT, reduce the hardness of PLA when used alone, improve its toughness, and finally get a product with good comprehensive performance. Therefore, using PLA to enhance the modification of PB3ATis a very efficient method.2.In terms of degradation performance.

In the initial stage of degradation, water molecules enter and hydrolyze the biodegradable materials.Single PBAT material, its own molecular structure has a rigid ester bond, water molecules are not easy to enter; On the contrary, water molecules are easy to enter and undergo internal degradation.

The higher the content of PLA, the faster the degradation of plastic.3.The softening temperature is 58℃ when PLA is only added, so PBS blending modification is needed to Improve the softening temperature and the softening point can reach 100℃.

The product can be heated in the microwave for 10 minutes and can withstand 100 degrees of hot water.

-

Current major biodegradable plastics introduction

PLA

PLA ls a biodegradable material, made from starch derived from renewable plant sources such as corn.

Using starch as raw material, glucose was prepared by sanctification, and then high purity lactic acid was obtained by fermentation with glucose and certain strain, and then certain molecular weight polylatic acid was synthesized by chemical synthesis method.

It has good biodegradability and can be completely degraded by microorganisms in nature after use, eventually producing carbon dioxide and water without polluting the environment.

PBAT

PBAT is a thermoplastic biodegradable plastic which is a co-polymer of butanediol adipate and butanediol terephthalate.

It combines the properties of PBA and PBT, and has good ductility and elongation at break, as well as good heat resistance and impact proper-ties.

In addition, it has excellent biodegradability.

PBS

PBS is a completely biodegradable plastic with good neat resistance, mechanical processing properties, bio compatibility and mechanical properties. It is similar to traditional polypropylene, and it can be degraded under specific microbial conditions.

Its completely degradation products are not harmful to the environment. During normal storage and use, the performance of PBS is very stable, so it has excellent comprehensive performance.

-

Current certification of biodegradable materialism various countries.

-

America ASTMD6400

-

Germany DIN EN 13432

-

Austria TUV EN 13432

-

China ISO14024

-

China GB/T 41010

-

Australia AS4736

-

-

Advantages of our compounding solution

1.We have more application experience. Currently, more than 50customers around the world arousing our degradable material modification processing solutions.

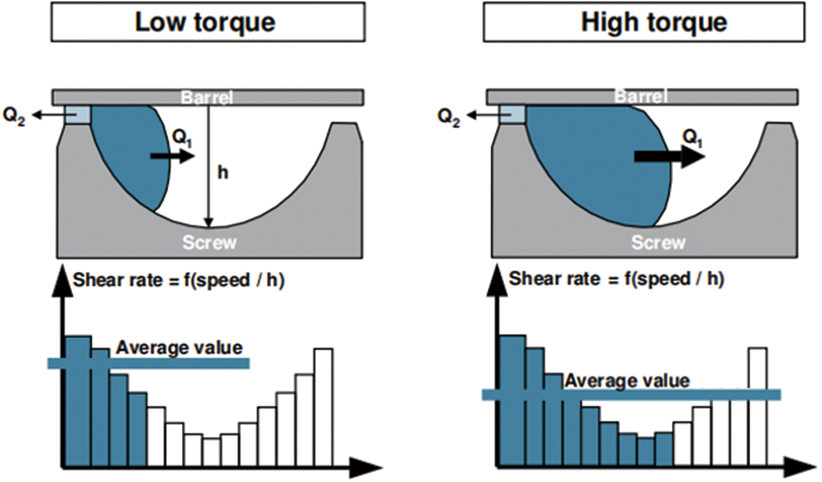

2.The higher the equipment torque grade, the lower the screw speed in operation, the smaller the aver-age shear rate of melt in the processing process,the larger the load, the higher the material filling degree, can obtain higher output.

-

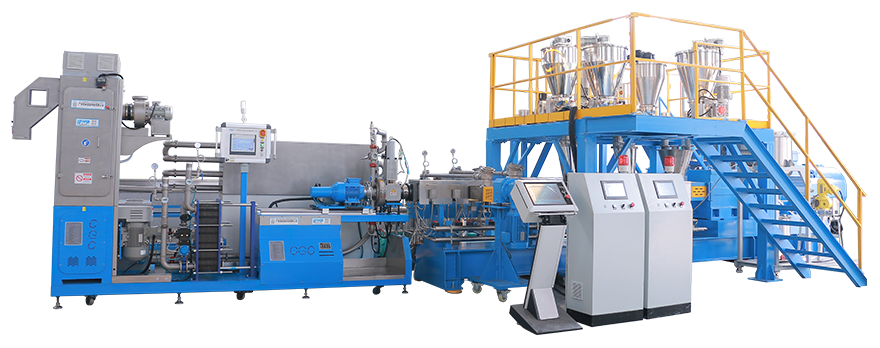

Bio-plastic compounding line

Middle and smaller capacity Bio-plastic compounding line

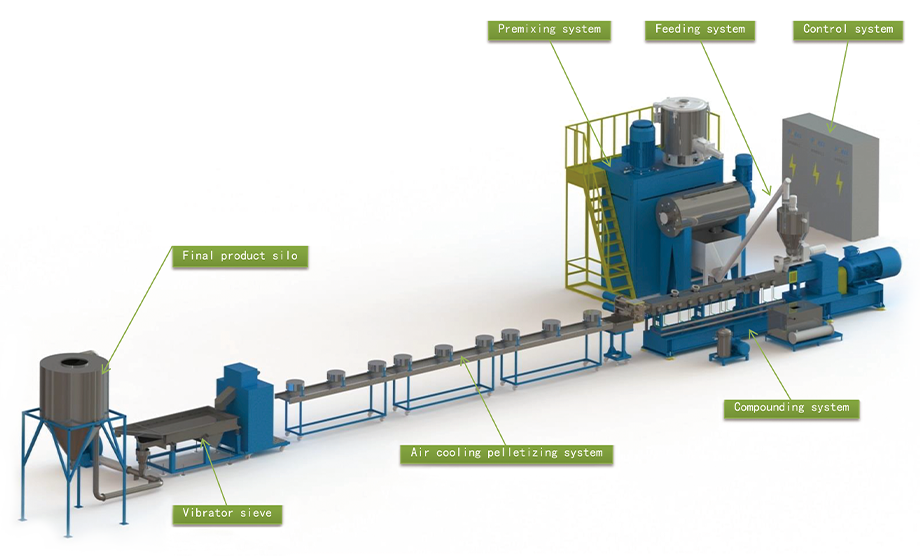

1.Special design for optional.

Special designed of PTFE coating on air cooling bed significantly reduce the sticky of melt on surface of the bed and prevent production break effectively. The front section of air cooling bed can be designed with closed cover and negative pres-sure air system to suck most of the smoke away to prevent workshop pollution.2.Premixing system

Raw material of bio-plastic, starch, biomass powder, mineral powder and different additives are put into high speed mixer together for significant premix before dumped into cooler mixer as a buffer for storage also.3.Compounding system

Modular twin screw extrude equipped with super high torque gearbox, wear resistant & corrosive resistant barrels and screw elements, high torque shaft and safety dutch, efficient heating and precise control to ensure stable,reliable and long term production.4.Simple and economical cooling and cutting

System Air cooling bed are designed with enough length to cool to melt strand off before cut by a traditional peletizer the whole system is simple and operated easily.

Starch filled Bio-plastic compounding line

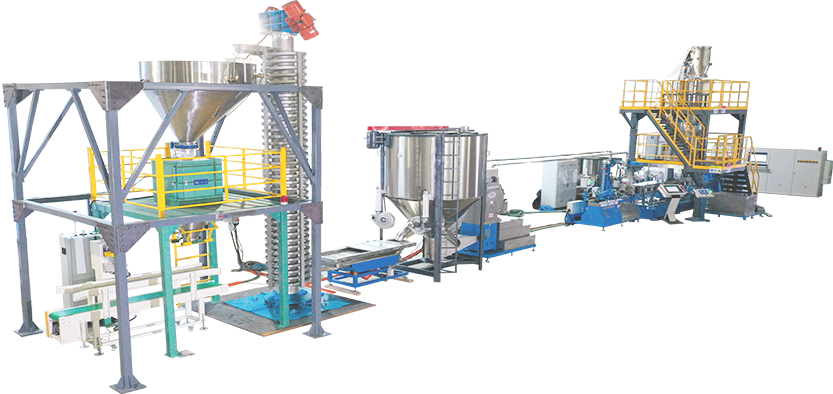

1.Dosing system

Raw material of bio-plastic, starch and plasticized are fed into twin screw extruded via accurate LW feeders separately with high automation and flexibility to adjust formulation.2.Compounding system

Modular twin screw extrude equipped with super-high torque gearbox, wear resistant & corrosive resistant barrels and screw elements, high torque shaft and safety dutch, efficient heating and precise control to ensure stable,reliable and long term production.3.Downstream auxiliary equipment

Rich and reasonable downstream equipment realize homogenization,sieving, drying & cooling until automatic packing smoothly.4.Underwater cutting system

Advance underwater cutting system can produce elliptical pellet with high automation, the closed system has no emission of smoke and dust to environment and can adapt to various capacity requirements.

Basic formula:

Bio-plastic +55%Starch +15%GlycerineHost features:

Hight torque,low rotating speed,andsmallshear,which can reduce damage to the ma-terials,andensure the good uniformity ofgranules.It also has a high capacity.